Modern vehicles are complex machines controlled by multiple Electronic Control Units (ECUs). The On-Board Diagnostics II (OBD2) system continuously monitors key vehicle systems and components to keep them running efficiently and within emission standards. At the heart of OBD2 diagnostics are two essential concepts: Diagnostic Trouble Codes (DTCs) and Parameter Identifiers (PIDs).

What are DTCs?

Diagnostic Trouble Codes (DTCs) are standardized codes that indicate malfunctions in a vehicle’s systems, especially related to the engine and emissions. When a sensor detects an abnormal condition, such as an oxygen sensor reading out of range or a cylinder misfire—it signals the ECU, which then logs a corresponding DTC.

Each DTC follows a standardized format:

- First character: Letter indicating the system

- P = Powertrain

- B = Body

- C = Chassis

- U = Network

- Second character: 0 = standardized (SAE), 1 = manufacturer-specific

- Next three digits: Specific fault code

For example, P0171 means “System Too Lean (Bank 1)”, which often relates to a vacuum leak or faulty fuel injector.

When a serious issue is detected, the ECU may trigger the Malfunction Indicator Lamp (MIL), commonly known as the “Check Engine Light.” Even if the light doesn’t turn on, a DTC may still be stored as a “pending” code and can be retrieved using an OBD2 scanner.

What are PIDs?

Parameter Identifiers (PIDs) are codes used to request real-time data from a vehicle’s ECU. These values provide live information on engine parameters and sensor outputs, which technicians and diagnostic tools can use to monitor how the vehicle is performing.

Common PIDs include:

- 0C: Engine RPM

- 05: Engine coolant temperature

- 0D: Vehicle speed

- 11: Throttle position

- 0F: Intake air temperature

Each PID returns a value in a specific format. For instance, PID 0C (RPM) returns a two-byte value that needs to be decoded using a formula defined by the OBD2 standard.

PIDs are essential for live diagnostics and preventive maintenance. By analyzing PID data, technicians can detect early warning signs, such as fluctuating fuel trims or temperature spikes, before they become serious issues.

How DTCs and PIDs Work Together

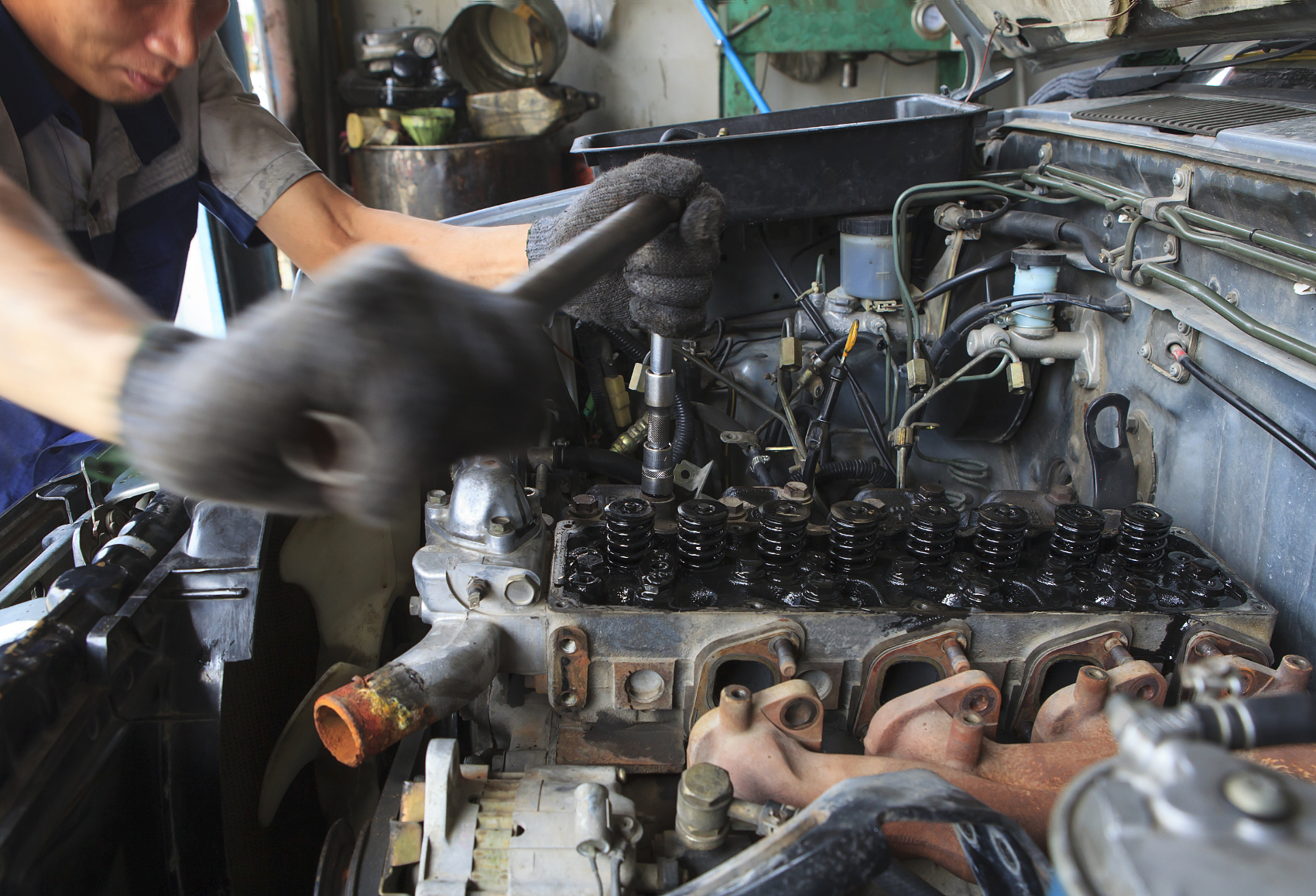

DTCs and PIDs complement each other in automotive diagnostics. Think of DTCs as error messages and PIDs as live data feeds. When a DTC is triggered, a technician can use PIDs to see how various systems are behaving in real-time and narrow down the root cause.

For example, a P0420 code (Catalyst System Efficiency Below Threshold) might lead a technician to check the upstream and downstream oxygen sensor readings using PIDs to determine if the catalytic converter is failing or if there’s a sensor issue.

Tools for Accessing DTCs and PIDs

To read DTCs and PIDs, technicians use OBD2 scanners or diagnostic tools, ranging from basic handheld readers to advanced software-based systems. These tools plug into the OBD2 port—usually located under the dashboard—and communicate with the ECU using standardized protocols like CAN, ISO 9141, or KWP2000.

Many consumer-grade OBD2 tools (and mobile apps paired with Bluetooth OBD2 adapters) can read basic DTCs and show live PID data. However, professional tools often offer access to extended manufacturer-specific codes, freeze frame data, mode 6 diagnostics, and advanced functions like active testing.

The OBD2 system, with its DTCs and PIDs, provides a robust, standardized framework for diagnosing vehicle issues and monitoring performance. While DTCs alert users to potential problems, PIDs offer the detailed insights needed to pinpoint faults and verify repairs. Together, they form the backbone of modern automotive diagnostics—helping ensure vehicles stay efficient, safe, and compliant with environmental standards.

Learn more details on : DO you know what is PID ?