The rise of electric vehicles (EVs) has reshaped the automotive industry over the past decade. With advancements in technology and growing environmental concerns, EVs have become a cornerstone of sustainable transportation. In this article, we’ll explore the role of EV OBD in battery pack management and data monitoring, and how it supports the growing demand for efficient and reliable electric vehicles.

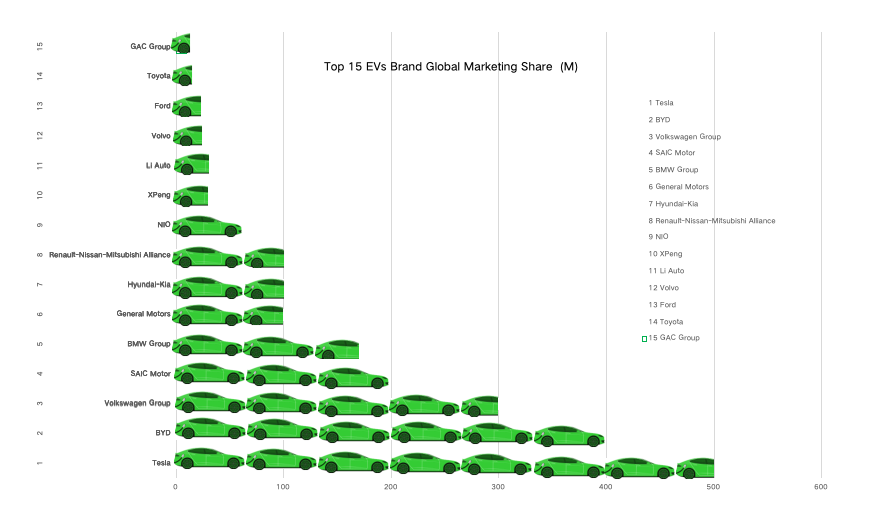

Over the past 5 years, the global adoption of new energy vehicles (NEVs), including battery electric vehicles (BEVs) and plug-in hybrid electric vehicles (PHEVs), has skyrocketed. In 2023, the global EV fleet surpassed 30 million units, a significant increase from just 5 million in 2018. Countries like China, the United States, and those in the European Union have led this transition, driven by government incentives, stricter emissions regulations, and advancements in EV technology.

Experts predict that by 2030, EVs will account for over 60% of new car sales worldwide This shift is fueled by the undeniable advantages of EVs over traditional internal combustion engine (ICE) vehicles: EVs produce zero tailpipe emissions, reducing air pollution and greenhouse gas emissions, Electricity is cheaper than gasoline, and EVs have fewer moving parts, resulting in lower maintenance costs, Electric motors deliver instant torque, providing a smoother and faster driving experience.

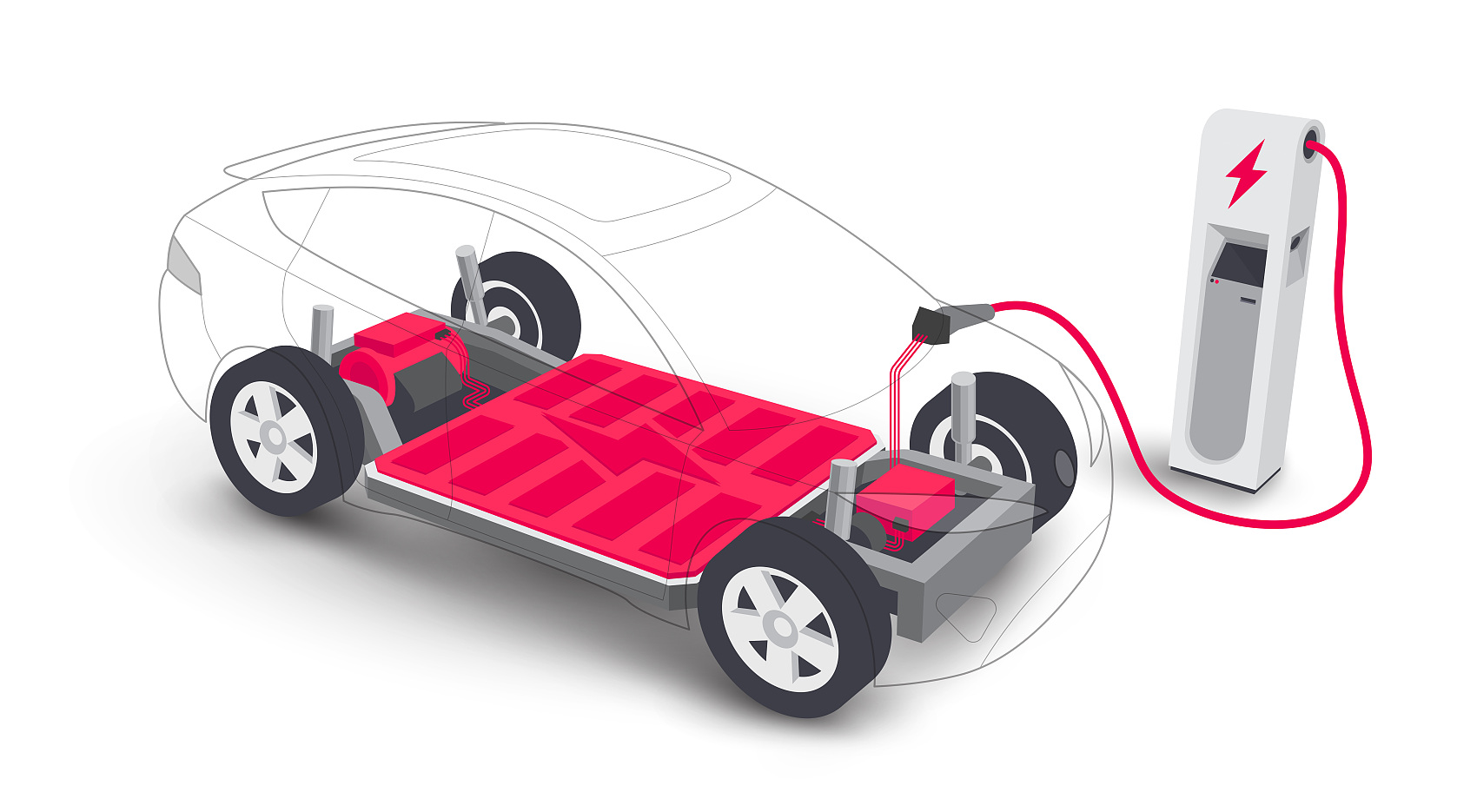

As the EV market continues to grow, the need for advanced battery management systems becomes critical. This is where EV OBD plays a transformative role.The battery pack is the most critical and expensive component of an EV, accounting for up to 40% of the vehicle’s total cost. Modern EVs primarily use lithium-ion batteries due to their high energy density, long lifespan, and fast charging capabilities. However, these batteries require precise monitoring and management to ensure optimal performance, safety, and longevity. Overheating, overcharging, or deep discharging can lead to battery degradation or even catastrophic failures. , Efficient battery management ensures consistent power delivery and maximizes driving range. Proper management extends the battery’s lifespan, reducing replacement costs.

This is where EV OBD systems come into play. EV OBD acts as the brain of the battery management system (BMS), providing real-time monitoring and diagnostics. Here’s how it works:

- Data Collection: EV OBD reads critical battery data, including state of charge (SOC), state of health (SOH), temperature, voltage, and current.

- Real-Time Monitoring**: The system continuously tracks battery performance, identifying anomalies such as overheating or voltage fluctuations.

- Data Upload**: The collected data is transmitted to a cloud-based platform via cellular or Wi-Fi connectivity, enabling remote monitoring and analysis.

- Predictive Maintenance**: By analyzing historical and real-time data, **EV OBD** can predict potential issues, allowing for proactive maintenance and reducing downtime.

For example, EV OBD can detect if a specific battery cell is underperforming and alert the driver or fleet manager. This level of precision ensures that the battery operates within safe parameters, enhancing both safety and efficiency.

Fleet management companies are increasingly adopting EVs to reduce operational costs and meet sustainability goals. However, managing a large fleet of EVs comes with unique challenges, particularly in battery monitoring and optimization.

How Fleet Managers Rely on EV OBD:

- Centralized Monitoring: EV OBD systems upload battery data to a centralized platform, allowing fleet managers to monitor the health and performance of every vehicle in real time.

- Optimized Charging: By analyzing battery data,EV OBD helps fleet managers optimize charging schedules, reducing energy costs and preventing battery degradation.

- Route Planning: Real-time battery data enables smarter route planning, ensuring that vehicles have sufficient charge to complete their trips.

- Cost Savings: Predictive maintenance and efficient battery management reduce repair costs and extend the lifespan of the fleet’s battery packs.

For instance, a delivery company using EV OBD can track the battery health of its entire fleet, ensuring that vehicles are always ready for operation. This level of control is essential for maximizing efficiency and minimizing downtime.

The rapid growth of new energy vehicles has highlighted the importance of advanced battery management systems. EV OBD is at the forefront of this transformation, providing real-time data monitoring, predictive maintenance, and optimized battery performance. Whether for individual EV owners or large fleet operators, EV OBD ensures that battery packs operate safely, efficiently, and cost-effectively.

As the EV market continues to expand, the role of EV OBD will become even more critical. By leveraging this technology, we can unlock the full potential of electric vehicles, paving the way for a cleaner, greener, and more sustainable future.